SPARK BUSTER antistatic filter technology

To preserve the environment oil producers are supplying a new generation of eco-friendly hydraulic and lubrication oils to OEM (Original Equipment Manufacturer) and system operators. These new products, unlike the previous ones (group I base oils) have the risk to generate electrostatic discharge.

In the past, conventional oils often contained ashes and zinc dithiophosphate (ZDDP) as anti-wear and anti-corrosion additives. They therefore no longer comply with the current international environment standards as they have now been classified as harmful.

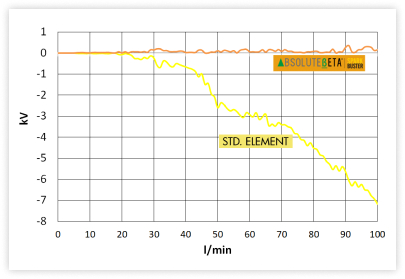

However, without the presence of metal, these oils have low conductivity (less than 500 pS/m). When the oil flows through the filter element in the hydraulic system, if it is not antistatic, an ESD can occur. This can result in sparking in the system causing oil aging and damage to components.

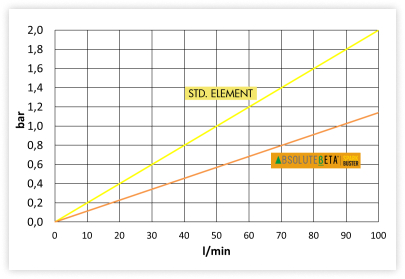

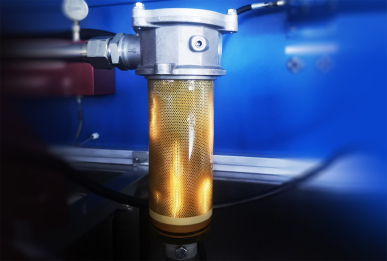

For several years FILTREC has anti ESD products in its range but now customers can also rely on our new ABSOLUTE BETA | SPARK BUSTER antistatic filter media, which provides an antistatic filter protection that not only reduces the electrostatic discharge but also enables excellent filtration in extremely critical systems.